The right material makes a big difference in the success of your labels, and few materials are better than BOPP. Short for “biaxially oriented polypropylene” (try saying that 5 times!), BOPP films are best suited for product owners who need a high level of performance. We’ve printed BOPP labels for a variety of markets like food, bath, beauty, industrial, and more. If you’re unsure if BOPP is right for you, below is a list of benefits, material options, and other considerations to help you decide.

Before we get into the nitty gritty details…it’s important to note that there are two categories of BOPP materials: stock and finish. We have ready to print in-stock materials, like metalized silver BOPP (stock) and BOPP laminates (finish) that are applied to the stock of your choice. We’ll get to these materials in a bit.

Benefits of BOPP Film Labels

One of the biggest differences between regular polypropylene and BOPP is how they’re made. (Technical Jargon Warning! If you bore easily, just skip to the advantages in the bullet points.) During manufacturing, regular polypropylene is extruded – a process that stretches and pulls the material through a die – in a single direction whereas BOPP is stretched in two directions, hence the name “biaxially.” This process gives BOPP some advantages over polypropylene, such as:

- Higher gloss and clarity

- Higher tensile strength that facilitates high-speed printing

- Greater stiffness

- Excellent printability

- Moisture and abrasion resistant

- Oil, chemical, and acid resistant

Polypropylene shares most of these characteristics, but the bottom line is that BOPP looks and performs better because of how its made. Many brand owners, however, find that regular polypropylene more than meets their label needs and better fits their budget than BOPP which can have a higher price per label. For situations that require labels to be more durable, BOPP is a step up from polypropylene. It’s important that you let us know your label requirements and the conditions your labels will face so we can help you choose a material that best fits your needs.

If BOPP is more aligned with your label goals, below are several options to consider when selecting your label materials.

Different Looks, Same Performance Level

We’re all about customizing labels, and BOPP labels are no different. That’s why we offer different options so you can select one that works best for your artwork, product, and brand.

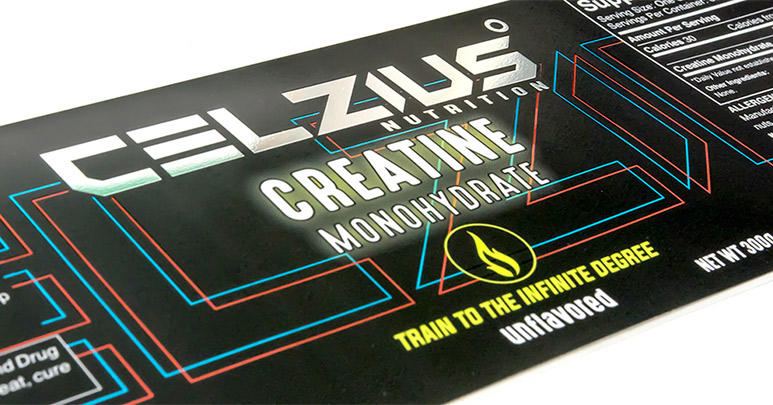

- Metalized silver: Add a mirror-like shine to your products with metalized silver BOPP. We can tint the whole label or certain parts to any color depending on your label design. For areas you would like to be opaque with no shine, we would have to do white underprinting so the colors aren’t altered by the metallic film underneath.

- Opaque white: White labels offer a classic look and various design opportunities. The great thing about white labels is that since it’s already white, we don’t need to underprint colored inks with white ink since the film gives the inks opacity.

- Clear: Perfect for achieving an elegant “no label” look, clear labels are a popular choice for bath and beauty products. Since BOPP is extruded twice, BOPP is clearer and shinier than polypropylene. Clear labels, however, often requires white underprinting so the inks aren’t transparent (unless that’s part of the label design).

The main difference between these options is appearance so the one you choose will largely depend on the container you’ve chosen and the look you are trying to achieve. Having your label design and container ready before you select a material will help you see which material will look best.

BOPP films are an excellent choice for labeling projects that require more out of their labels whether it’s looks, durability, or both. To get started on your custom BOPP labels, give us a call at 1-800-475-2235 and we’ll help you turn your label goals into reality.

Sources:

http://impexfilms.com/products/biaxially-oriented-polypropylene-films-bopp

http://www.innoviafilms.com/About/Manufacturing/BOPP.aspx