Properly Labeling Pharmaceutical and Healthcare Products

One of the main responsibilities of the Food and Drug Administration (FDA) is regulating the labeling standards for pharmaceutical, medical, nutraceutical, and dietary products. We’ve compiled a list of guidelines so you can better understand pharmaceutical labels and healthcare product labeling. Whether you’re labeling prescription drugs or medical devices – all pharmaceutical and healthcare products must be labeled correctly for consumer safety.

1. Labeling Responsibilities

According to the FDA, all labels printed for use in the pharmaceutical and healthcare industry are required to be designed and applied so they can remain in place and be read in different environments through distribution, storage, and use.

The label manufacturer is responsible for making sure that the print is legible and will remain that way throughout the product’s lifespan. Product manufacturers are responsible for complying with content and format requirements – click here for more information on FDA regulations.

2. Displaying Product Information

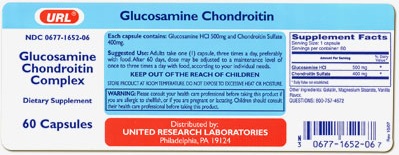

All types of labeling have content requirements for what types of information and claims can be stated on a label. Each drug and medical device classification has their own set of requirements for what information should be shown on the product. Several important things to include on a pharmaceutical or healthcare product label:

- Official product name

- Active and inactive ingredients

- Drug Facts table

- Purpose and use

- Warnings

- Directions

- Allergic reactions

3. Formatting Labels for FDA Approval

Your labels must be designed in the appropriate FDA format for your product’s classification like OTC medications, oral contraceptives, combination products, etc. Click here for a list of labeling guides relating to drugs. Some things you should consider when designing labels for FDA approval:

- Font size and type (must be legible)

- Language (appropriate use of abbreviations, grammar, advertised claims, etc.)

- Format (organization and appearance of sections like Drug Facts, warnings, uses, etc.)

- Materials (depending on the nature of the product)

4. Choosing Approved Materials

Label materials for pharmaceuticals aren’t as stringently regulated as the packaging/container that will touch the drug product. Your label materials can be made from standard white paper stock to holographic films to shrink sleeve labels, depending on what you want the label to do.

Multi-layer labels are often used because pharmaceutical and healthcare products are required to share large amounts of information. For further product safety, you should choose adhesives, coatings, and inks that are “low migration” meaning that little to no substances transfer from the materials to the drug or device.

5. Controlling Label Quality

Every label printed should be inspected thoroughly to ensure the information is consistent and accurate. Industry standards must be met for safety and liability reasons which is why it’s important to discuss with your label manufacturer their quality control processes

- Printing multiple pharmaceutical labels: The products should be separated to prevent any mix-ups or switches. Product separation can be physical or spatial or can be completed by performing press runs at different times to avoid confusion. Ask your label manufacturer whether the areas around the presses are completely cleared from previous print jobs – this provides less room for any printing errors.

- Proper control of storage: An important consideration, proper storage control is necessary for preventing any mix-ups or switches when dealing with labels printed for use in the pharmaceutical industry. After your labels have run and before they are issued for use, you should carefully examine them to ensure they comply with your specifications and FDA standards.

We carry a variety of FDA approved materials to satisfy industry labeling requirements and achieve the look you want. Get started on your custom pharmaceutical labels by getting an instant online quote!