Products with oily or greasy contents – like essential oils, beard balms, and sauces – create special labeling challenges because the oils can deteriorate a label’s quality or cause adhesion issues if the wrong materials are used. Whatever product you’re labeling, the contents should always be considered when selecting label materials so you don’t end up with these (or other) unpleasant surprises. Let’s take a look at the best labeling materials to use for oil-based products, and give you a head start toward your product’s success.

First, let’s take a quick look at why oils cause label issues. Common problems we’ve seen with oil-based products are:

- Spilled oil seeps in between layers of label material which can cause paper labels to soak up the oil and deteriorate the label’s quality.

- The spilled oil smudges and distorts the printed image on the label (not a pretty look) which can also cause inks to transfer from the label to whatever contacts it (fingers, clothing, etc).

- The product has oil on its surface prior to labeling, making it harder for the label’s adhesive to create a bond.

Now that you know the things that can go wrong when labeling oil product, check out our material tips below to see how you can avoid these problems.

Be a Film (Material) Star!

There are dozens of materials that can be used for custom labels, but to keep things simple, label materials fall into two categories – papers and films. There are benefits and drawbacks to either type of material, but one material will be better suited for your labels than the other, depending on your needs and budget. For oil product labels, we recommend you select a film material for its resistance to oils and other liquids, versus the absorbent nature of paper labels.

Film typically costs a little more than paper, but it’s an investment worth making to ensure your labels can handle oils and other greasy substances. Of course, this doesn’t mean you can’t use paper. There are plenty of oil-based products that use paper on their labels, but knowing how it will affect your product longer-term is our goal. The decision is ultimately yours.

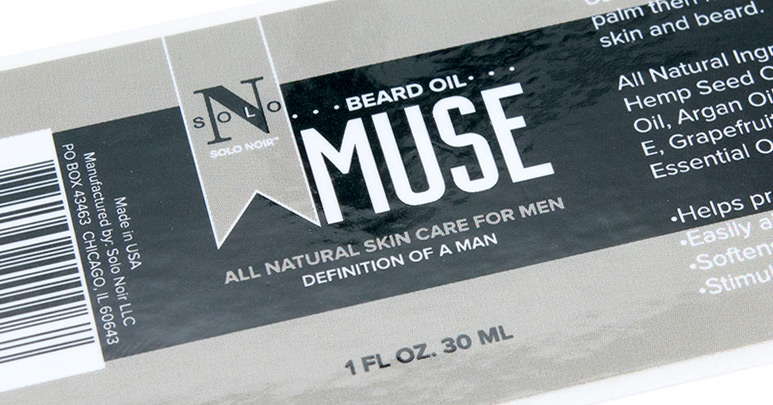

Now that you know that film is best suited for labeling oil products, the next question is what type of film should you use? Well, it depends on what type of look you are going for! Here are some film options to consider when buying custom labels for oil-based products.

- White, opaque film: White polypropylene film is a versatile material that can blend into white containers or contrast against a colored container. This material is used in a variety of markets like food, automotive, and bath & beauty. We also have white vinyl film if you need stronger labels – perfect for outdoor use or industrial labeling. Most label buyers will find that white polypropylene has more than enough durability to meet their needs.

- Transparent film: Clear polypropylene film creates a “no label look” on glass, plastic, clear or dark colored containers. When designing artwork for clear labels, make sure you or the designer make a note of which parts should be backed by white ink so the artwork is opaque – unless that’s what you want. We also have glossy and matte clear films to match your container’s texture; this is important because a glossy clear label on a matte texture container will not blend, and vice versa.

- Shiny foil film: Metalized foil film is similar to white and clear films as far as repelling oils and liquids, but looks-wise, they couldn’t be more different. With its mirror-like reflectivity, foil film can make your product and brand look premium without much effort. Furthermore, foil film offers design versatility – it can be tinted to any color, left as is, or be multicolored. Another option you can consider is holographic-patterned film that moves and shimmers when light hits it – perfect for grabbing customers’ attention as they walk down a store aisle.

- Shrink sleeves: This unique label product is different than standard pressure sensitive labels as they’re shrunk onto a container using heat. The end result is a label that form-fits to your container with 360-degree graphics coverage. Shrink sleeves are printed on polypropylene or polyester film material that can withstand moisture and friction without damaging the printed image. Shrink sleeves, however, have special equipment requirements for application (e.g. a heat or steam tunnel to shrink the sleeves onto the container) that need to be considered.

A Quick Word on Adhesives…

In “Label Adhesives Guide Part 2: Performance Factors,” we discuss different factors that can affect an adhesive’s performance, one of them being container cleanliness. Adhesives work best on clean surfaces, but sometimes that’s not always possible due to manufacturing processes. If oil will seep onto the container while it’s being packaged, it’s a good idea to order a more aggressive adhesive that will create a more durable bond between the label and container.

When picking a label material for oil products, it’s important that it not only repels oil but also looks good while doing it. We suggest going with film materials like the ones we discussed, adding a polypropylene laminate finish for extra protection, and selecting a stronger adhesive if oil contamination on the container is an issue. Don’t worry though, our customer service reps can help you pick a label material that will work best for your product, packaging, design, and budget. Or if you have a material in mind that you feel confident using, you can get started with an online quote to get pricing, submit artwork, or create an account.