The concept of custom labels is relatively simple: create a design and print them. But getting successful custom labels (meaning they print well, look appealing and stick properly) can be a different story, especially if you’re new to the label world. Let’s say you’re a juice startup looking to break into the cold-pressed juice market. One way to make your packaging attractive to consumers is with custom labels that complement the container and express your brand. Not only should your juice labels be appealing, they should be able to withstand cold temperatures, moisture, and friction. Here are some considerations that can help make the whole process easier.

1. Give yourself (and your label company) enough time. Research and planning can go a long way in making your experience less stressful for everyone. We understand that some customers need labels NOW (hence our rush ordering option), however, you should try to avoid that extra pressure, and cost, if possible. Give yourself enough time to brainstorm different looks and material options, as well as time to work on the label design. By not rushing, you also will help give us plenty of lead time and fewer chances of running into problems that could delay production.

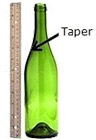

2. Determine a shape and size that works with the container.  An easy way to determine the size of your labels is to measure the height and width where the label will be applied. If you have a bottle or round container, you can use a measuring tape to find the circumference. No measuring tape? No problem. Just take a sheet of paper, and wrap it around the bottle. Then mark on the paper where it overlaps, and measure the distance between the paper’s edge and the mark to find the circumference. We strongly suggest you determine the label’s size and shape before designing anything to avoid unnecessary reworks.

An easy way to determine the size of your labels is to measure the height and width where the label will be applied. If you have a bottle or round container, you can use a measuring tape to find the circumference. No measuring tape? No problem. Just take a sheet of paper, and wrap it around the bottle. Then mark on the paper where it overlaps, and measure the distance between the paper’s edge and the mark to find the circumference. We strongly suggest you determine the label’s size and shape before designing anything to avoid unnecessary reworks.

Bonus Tip! Be sure to let your label rep and designer know if there is any tapering or curves on the container. This information will help us determine which shape your labels should be to ensure a proper fit.

3. Draw inspiration from others, but don’t copy. Look at competitive products on the shelf to see what designs and colors you are being compared to so when the label is designed it stands out from the competition. One way to organize your thoughts is to create an inspiration board (whether it’s just taping clips to your wall or using Pinterest) and add anything that catches your eye. This will help you or the designer get a better idea of how to proceed, and increase the chances of getting the design you want more quickly.

4. Work with a professional label designer. Designing cool artwork is hard, especially if you don’t have the technical know-how! We advise you hire a professional label designer that can turn your design ideas into reality and ensure that your artwork is ready for high-quality printing. A professional can also give more honest and useful feedback/suggestions than friends, employees or family.

5. If designing on your own, keep the artwork simple and use the right tools. Sometimes hiring a professional label designer isn’t in the budget, but don’t worry, you can still achieve great looking labels on your own. Before you start designing, though, there are a couple considerations to keep in mind. First, use graphic design software, like Adobe Illustrator, that can work with vector graphics (click to see why vector matters). Next, avoid putting too many graphics, colors, fonts, etc. because it can result in a cluttered looking design. Simplicity never goes out of style. (Of course, designing in CMYK color and creating your label in the actual size it will print are important too!)

6. Give us ALL the details of your project. The more information we have on your labeling project, the easier it will be to help you meet (or exceed!) your expectations. We consider ourselves “label detectives” – we’re trained to ask a lot of questions and sniff out the information needed to achieve a quality label product. However, it’s helpful to us when customers have their project’s details readily available because we can make better suggestions on the spot, and move the order faster since we’re not waiting on information.

Bonus Tip! A good point to mention to us is how you’re applying the labels because applying by hand or using a machine applicator can impact your label options. For example, clear labels look best when applied by a machine because creases and bubbling are more likely to happen when applied by hand.

7. Discuss customization options with your rep.  There are a variety of methods we can use to make your labels unique, including eye-catching materials, special finishes, custom shapes, and many more. A star-shaped label printed on metallic silver paper is more likely to stand out than a rectangle label printed on semi-gloss paper. Depending on what look you’re going for and your budget, our label experts can guide you through the many different customization options that can make your labels “pop.” (We can also provide a sample packet in case you want to see and feel our custom labels.)

There are a variety of methods we can use to make your labels unique, including eye-catching materials, special finishes, custom shapes, and many more. A star-shaped label printed on metallic silver paper is more likely to stand out than a rectangle label printed on semi-gloss paper. Depending on what look you’re going for and your budget, our label experts can guide you through the many different customization options that can make your labels “pop.” (We can also provide a sample packet in case you want to see and feel our custom labels.)

Like most things in life, a little planning goes a long way. Hopefully, these considerations have given you a better idea of how to get labels that achieve your project’s goals and add value to your product or service. And when in doubt, ask your label printing company lots of questions (that’s what we’re here for).