When it comes to printing labels, the shape you choose matters for a number of reasons. Most of our customers tend to know what shape they want before coming to us, however, it’s not uncommon for them to change their minds once we explain what’s involved in getting a custom shape, or why a certain die cut is superior over another to achieve high-quality printing. Read on to find out how shape can impact your design choices so you can make better, more informed decisions on your next label order.

Packaging Considerations

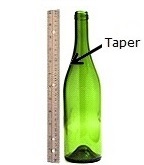

The variety of bottles and containers for product owners to choose from is practically limitless…and partly why we carry over 3,000 custom die shapes. A bottle that has straight, smooth sides can work with many different shapes because it won’t distort how the label looks once applied. If the bottle tapers, even in the slightest, it can present a labeling challenge because the shape will need to be curved enough to ensure a proper fit.

Be aware, however, that a custom shape may be needed for tapered bottles (especially if the label will be applied to the tapered area) which can result in die tooling fees. Typically a one-time fee, custom tooling can range between $200 – $600 depending on your label shape and specific requirements.

TIP! An easy way to determine whether your bottle or container is tapered is to put a ruler or hard book against the side. If you see any space in between the bottle and ruler, you got yourself a taper.

Design and Label Shapes

Getting your labels custom printed gives you more control over the label’s final look, but printability and aesthetic issues can arise if the design doesn’t lay out well within the label’s shape. To make it easier for you to understand the pros and cons of different label shapes, we’ve grouped together five basic types we often print so you can have an easier time deciding which shape is best for your needs.

- Rectangle: Most of the labels we produce are rectangle because this shape allows for the most design space. There are two types of rectangle shapes to know – round and square corners. Rectangle labels with rounded corners won’t easily flag (i.e. when a label corner lifts up from the surface) which is why the majority of rectangle labels are printed with rounded corners. The other option, square corner labels, can have a more contemporary appearance but is more prone to flagging since the pointy edges can get caught by something and lift up more easily.

- Square: Different sizes of square labels work well for achieving certain label looks. For example, small square labels with simple text and graphics can be used as a warning label for industrial products. They can also be used as inventory labels, remember-the-date stickers, barcode labels and more. Larger sized square labels have more space for multiple design elements like a logo, graphics, images, and text which can be useful for attracting attention to promotional labels like and coupons.

- Oval: An effective way to achieve an elegant label look is to make them oval. Used across a variety of markets – such as food, beverage, and bath & beauty – oval labels look great with minimalistic designs. That’s because oval labels have less design space than rectangle labels, and the oval shape can impact how text looks by making it curved to fit within the label. Also, it’s important that the artwork fits well within the oval label’s die line (where the label is cut) to better ensure printing consistency.

- Circle: Like oval labels, a circle shape can add visual interest to stickers and labels but limits how much design can be printed. Bright circle stickers are a great way to advertise your latest promotion without spending extra money on changing your primary label. Circle labels can also be used to add a professional touch to mailing correspondence and marketing collateral – all you need to do is add your logo to the circular label design.

- Custom: One approach to make your labels really stand out is to go with a custom shape that complements your label design. Be aware, however, that getting a custom shape can cost you extra if we don’t have the exact shape and size you’re looking for because a custom die would need to be ordered. If you do decide to get a custom shape, you will be charged a one-time tooling fee. Save some time and resources on your next order by using a custom shape that’s already in our die inventory.

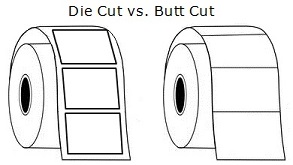

TIP! One way you can save on die charges is to have your labels “butt cut.” What that means is that the labels are sliced into rectangles or squares without there being any space in between each label. Butt cut is only recommended for labels that will be hand applied because machine applicators can’t apply labels in this format.

Give Us a Sample Bottle

If you’re still not sure which label shape to choose, we would be glad to consult with you one-on-one about different shape options. Customers often send us a sample of their bottle or container so we can see exactly what’s needed to achieve optimally printed labels. We also have several design resources that can help you or a designer better prepare the label’s artwork for high-quality printing. While you’re at it, check out our label size calculator for suggestions!