A label material we use often for these types of products is white pearlescent polypropylene, a semi-conformable film. Often, high-pressure processing is used in place of heat pasteurization for juices and we also have labels that can be used with this process, such as white BOPP film with UV gloss lamination which has excellent moisture resistance.

We don’t recommend applying shrink sleeves with a blow dryer, heat gun, microwave, or shrink wrap tunnel because shrink sleeves need to be applied with a uniform spread of heat.

Shrink sleeves are a unique print product that makes products stand out – adding texture to them increases the “wow” factor and makes your brand stand out in a sea of competitors. We’re able to add texture to shrink sleeves by using a Rotary Screen Integration (RSI®) system with capabilities to incorporate custom special effects like texture and other creative finishes

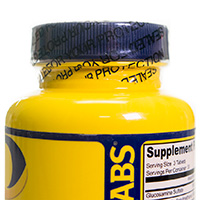

Tamper-evident seals can be printed in several styles to fit different security and packaging needs. One cost-effective option is to use a blank or custom label and apply it to the product’s cap to show that the product hasn’t been opened. If you’re looking for a higher level of protection, however, we recommend shrink sleeve labels with a perforated seal or shrink bands.