Semi-gloss paper is the most widely used label material because it has a great printing surface and is very cost effective. Another popular label material is film because it’s water resistant and works well with squeezable containers.

There are hundreds of label materials. Generally, labels are made from paper, vinyl, polyester, polyethylene and other types of specialty films.

We offer a wide variety of laminate types, however, polyester laminate is best for outdoor label applications.

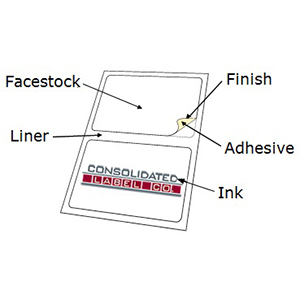

The layers of a label are as follows (starting with the bottom layer): release liner, adhesive, facestock, ink, and finish.

Adding either type of finish provides an extra measure of protection for the label’s inks.

It’s important to understand what type of label adhesives are available and how they differ. Within the pressure-sensitive adhesive category, there are three main classifications: permanent, removable, and repositionable.

A label material we use often for these types of products is white pearlescent polypropylene, a semi-conformable film. Often, high-pressure processing is used in place of heat pasteurization for juices and we also have labels that can be used with this process, such as white BOPP film with UV gloss lamination which has excellent moisture resistance.

Label adhesives are available in different strengths but there are factors outside of the adhesive that can affect its performance – in particular, the surface that the adhesive comes into contact with is crucial to how it will perform. Why label adhesives perform differently on different surfaces is due to the composition, texture, shape, cleanliness, and temperature of the surface.

Yes – your labels can have both gloss and matte finishes. Sections of your labels can be applied with a spot UV coating to add a matte finish to parts of glossy labels or protect aesthetic effects like accent colors, foils, textures, etc.

We recommend using durable, weatherproof materials like vinyl and polyester films since they can withstand freezing to hot temperatures (-50 to 200 degrees) and other elements like sun, chemicals, and abrasion. For further protection, don’t forget to include a durable laminate for outdoor use.

Using fade-resistant inks for outdoor applications instead of regular water-based inks will help increase the lifespan of the label because it has higher grade pigments that will fade less in sun exposure.

Pressure sensitive adhesives (aka ‘self-stick’ adhesives that don’t require solvents or heat to activate the adhesive) shouldn’t be used in the oven or microwave for a couple of reasons.