If your labels will be used for a short period of time, such as within six months, the majority of label materials will work for your application. On the other hand, if your labels will be outside, or face extreme conditions (freezing temperature, chemical exposure, etc.), or need to last for years, then it’s important to let us know so we can select a label material with a service life that fits your labeling needs.

Using label materials that aren’t designed for freezing conditions can cause issues with looks and performance which is why we recommend using a freezer-grade label material like white polypropylene film with an all-temperature adhesive.

There are several possibilities that can explain why your label is curling up, fortunately, most of them are relatively easy fixes: your label material may be too thick or stiff, your container shape is tricky to label, you’re not using a permanent label adhesive, or your label has square corners.

Direct thermal printing is a specialized printing technology that uses rapidly heated pins that selectively activate a heat sensitive coating applied to the facestock thus forming the desired image. Thermal transfer is thermal printing process using a temperature sensitive ribbon that through heat and pressure is selectively transferred to a printable surface thus creating the desired image. The ink is transferred from the ribbon to the print surface thus the term “thermal transfer.”

If you’re running into the issue of your label not sticking to the container or application surface, there are several reasons why this is happening and what you can do to fix it. Variables like container cleanliness, texture, shape, temperature, and environment can affect how well your adhesive works.

Bottle flaming is an in-line surface treatment for caps, bottles, and lids to ensure that labels will not peel off before the label comes to the end of its lifespan. This treatment is used for bottle materials that are “chemically inert” and won’t bond with glue.

Shrink sleeves are a unique print product that makes products stand out – adding texture to them increases the “wow” factor and makes your brand stand out in a sea of competitors. We’re able to add texture to shrink sleeves by using a Rotary Screen Integration (RSI®) system with capabilities to incorporate custom special effects like texture and other creative finishes

There are several reasons why you should use flexible packaging for gel products like product protection, consumer convenience, and design appeal – but which type of flexible packaging should you use? We recommend using sachets (aka packets) and pouches for gel-like products like lotions, shampoos, energy gels – basically anything that is viscous.

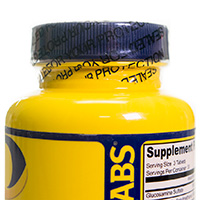

Tamper-evident seals can be printed in several styles to fit different security and packaging needs. One cost-effective option is to use a blank or custom label and apply it to the product’s cap to show that the product hasn’t been opened. If you’re looking for a higher level of protection, however, we recommend shrink sleeve labels with a perforated seal or shrink bands.